Granites

Half Dome, a granite feature in Yosemite National Park

Granite has been quarried for millennia on every continent except Antarctica. It is processed into everything from wall stones and cobblestones to countertops and gravestones. The streets in many cities in the eastern U.S. were originally paved with granite cobblestones (commonly now covered with asphalt). These cobblestones came from local quarries as well from overseas quarries as ballast on sailing ships. Granite is probably the most widely quarried type of stone worldwide.

To a geologist, the term granite refers to an intrusive igneous rock (one that crystallized below the earth’s surface) that contains a very specific suite of minerals – primarily quartz, feldspar, amphibole and biotite. These minerals give true granites their characteristic pinkish color as shown on the right.

To a geologist, the term granite refers to an intrusive igneous rock (one that crystallized below the earth’s surface) that contains a very specific suite of minerals – primarily quartz, feldspar, amphibole and biotite. These minerals give true granites their characteristic pinkish color as shown on the right.

In the stone industry, we dispense with this narrow definition and use the term granite for almost all igneous rocks, with the exception of volcanic ashes, and nearly all metamorphic rocks, with the exception of marbles and quartzites. This is a useful convention because most crystalline igneous and metamorphic rocks have similar physical properties – tight interlocking crystals, very low porosity, and high density (relative to most sedimentary rocks). Because of these physical characteristics, granites are generally the most durable of building stones.

Quarried granites range in color from very light gray to black and almost every color in between. The color is determined by the minerals that comprise the granite. Light colored minerals like quartz and feldspar create a light-colored granite. Dark iron- and magnesium-rich minerals like pyroxene and amphibole make for dark gray and black granites. Since the dark-colored minerals are denser than the light-colored minerals, dark granites are denser that the light-colored granites. While the density of a light gray granite may be as low as 165 pounds per cubic foot, the density of the darkest granites can be over 200 pounds per cubic foot.

Quarried granites range in color from very light gray to black and almost every color in between. The color is determined by the minerals that comprise the granite. Light colored minerals like quartz and feldspar create a light-colored granite. Dark iron- and magnesium-rich minerals like pyroxene and amphibole make for dark gray and black granites. Since the dark-colored minerals are denser than the light-colored minerals, dark granites are denser that the light-colored granites. While the density of a light gray granite may be as low as 165 pounds per cubic foot, the density of the darkest granites can be over 200 pounds per cubic foot.

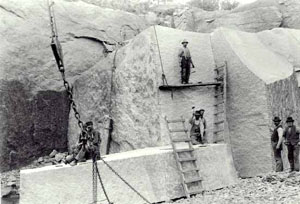

In the 19th and early 20th centuries, granite was quarried commercially throughout New England and the Mid-Atlantic states as well as in many other parts of the United States. Since shipping was exorbitantly expensive in the early days, each quarry serviced a relatively small area. Nowadays, with modern transportation, most of the smaller granite quarries have closed, with only a few active granite quarries remaining in Vermont, New York, Massachusetts, South Carolina, Georgia, Minnesota and South Dakota. These remaining quarries face brutal competition from quarriers in countries like China and India where labor costs are much lower.

In the 19th and early 20th centuries, granite was quarried commercially throughout New England and the Mid-Atlantic states as well as in many other parts of the United States. Since shipping was exorbitantly expensive in the early days, each quarry serviced a relatively small area. Nowadays, with modern transportation, most of the smaller granite quarries have closed, with only a few active granite quarries remaining in Vermont, New York, Massachusetts, South Carolina, Georgia, Minnesota and South Dakota. These remaining quarries face brutal competition from quarriers in countries like China and India where labor costs are much lower.

Granites are usually quarried in large rectangular blocks. In the quarry, the blocks are delineated by drilling closely-spaced holes. Either wedges or expanding materials are put into the holes to break the block loose. This process has certainly been improved with modern technology, but in essence hasn’t changed for hundreds of years. The blocks are then sawn into slabs or otherwise broken down into sizes and shapes useful as building or paving stones. The majority of granite today is sold as sawn slabs for panels and counter tops and as custom pieces for memorials (gravestones); however, there are still a few granite quarries that produce building stones as their primary products.

Granites are usually quarried in large rectangular blocks. In the quarry, the blocks are delineated by drilling closely-spaced holes. Either wedges or expanding materials are put into the holes to break the block loose. This process has certainly been improved with modern technology, but in essence hasn’t changed for hundreds of years. The blocks are then sawn into slabs or otherwise broken down into sizes and shapes useful as building or paving stones. The majority of granite today is sold as sawn slabs for panels and counter tops and as custom pieces for memorials (gravestones); however, there are still a few granite quarries that produce building stones as their primary products.

Granites usually have the highest compressive strengths and lowest water absorptions of any of the common building stones (click ASTM for an explanation of stone testing). They are typically the most resistant stones to staining and deterioration by acid rain and, due to their hardness, are also difficult to vandalize. Granite colors rarely change from exposure to the elements. If you are looking for the most resistant building material ever produced, granite is the answer.